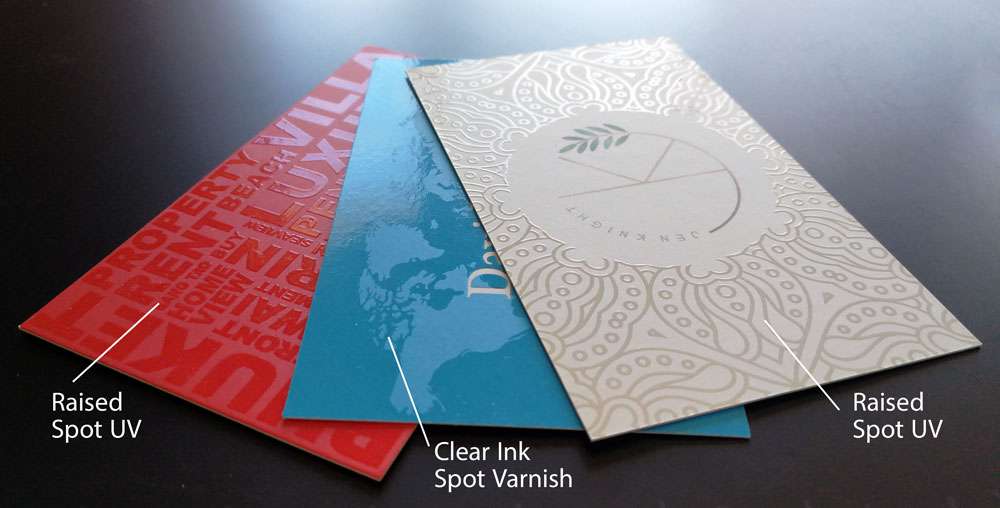

Creating eye-catching marketing collateral that leaves a lasting impression is crucial. Two popular techniques for achieving this are Raised Spot UV and Clear Ink Spot Varnish. These methods enhance your printed pieces, adding a touch of elegance and sophistication to your projects.

In this article, we will delve into the differences between Raised Spot UV and Clear Ink Spot Varnish, exploring their uses, advantages, and applications.#

The Purpose of Spot UV and Clear Ink Spot Varnish

Before we dive into the specifics, it’s essential to understand the primary purpose of both these techniques. Spot UV and Clear Ink Spot Varnish are utilized to enhance specific areas of printed materials, such as business cards, brochures, and packaging. They add visual appeal and a tactile element, making the design stand out.

Raised Spot UV: What Is It?

Raised Spot UV is a printing technique that creates a raised, textured effect on selected areas of your design. This process involves applying a clear, glossy coating to specific elements, resulting in a raised texture that not only looks stunning but also begs to be touched.

Clear Ink Spot Varnish: An Overview

Clear Ink Spot Varnish, on the other hand, adds a glossy, transparent layer to chosen parts of your printed material, creating a striking contrast between the varnished and non-varnished areas. This method provides a visually appealing, shiny finish.

Key Differences between Raised Spot UV and Clear Ink Spot Varnish

Now, let’s explore the fundamental differences between these two techniques.

- Texture: The most noticeable difference is the texture. Raised Spot UV creates a tactile experience, while Clear Ink Spot Varnish is smooth and glossy.

- Appearance: Raised Spot UV adds depth and dimension with a high gloss finish, making the design elements pop. Clear Ink Spot Varnish, on the other hand, offers a slightly less shiny, reflective surface.

- Durability: Raised Spot UV is more durable, making it ideal for items that will be frequently handled. Clear Ink Spot Varnish can wear off over time.

- Cost: Raised Spot UV is generally more expensive due to the additional printing processes involved. Clear Ink Spot Varnish is a cost-effective option.

- Timing: Raised Spot UV takes longer to print than the clear ink option. So if you’re in a hurry, the Clear Ink Spot Varnish would be the best option. (Pro Tip – Planning ahead always gives you more options and often lowers costs).

Advantages of Raised Spot UV

Raised Spot UV offers several advantages, making it a preferred choice for various applications:

- Eye-catching: The raised texture is impossible to ignore, making your design stand out.

- Tactile Experience: The tactile element engages the sense of touch, leaving a memorable impression.

- Durability: It can withstand wear and tear, ensuring your design remains intact.

- Luxurious Finish: The raised effect exudes sophistication and luxury.

Advantages of Clear Ink Spot Varnish

Clear Ink Spot Varnish also has its unique benefits:

- Glossy Finish: It provides a glossy finish that enhances the visual appeal.

- Cost-Effective: It’s budget-friendly, making it accessible for various projects.

- Versatility: It can be applied to a wide range of printed materials.

- Sleek Look: The smooth surface offers a modern and sleek appearance.

- Fast: It’s a relatively quick turnaround for small print runs.

When to Use Raised Spot UV

Clear Ink Spot Varnish is versatile and works well for a variety of projects. It’s suitable for brochures, flyers, postcards, and promotional materials where a glossy finish is desired.

How to Apply Raised Spot UV

Applying Raised Spot UV requires precision and expertise. It involves a specialized printing process that adds the raised texture to selected areas. It’s often done after the initial printing.

How to Apply Clear Ink Spot Varnish

Clear Ink Spot Varnish is relatively straightforward to apply. It’s a coating that’s applied over the printed material and cured using UV light. The varnish dries quickly, leaving a smooth, glossy finish.

Cost Considerations

While both techniques offer unique advantages, it’s essential to consider your budget. Raised Spot UV is a premium option and comes at a higher cost, while Clear Ink Spot Varnish is a more budget-friendly alternative.

Popular Applications of Raised Spot UV

Raised Spot UV is commonly used in various design projects:

- Business Cards: Adding a raised spot UV element makes your business cards memorable.

- Invitations: Wedding and event invitations benefit from the tactile and elegant feel.

- Packaging: Luxury product packaging often features Raised Spot UV for a sophisticated look.

The additional tactile effect of Raised Spot UV adds an extra level of quality that’s just as tangible as the quality of the card stock it’s printed on.

Popular Applications of Clear Ink Spot Varnish

Clear Ink Spot Varnish is suitable for different applications, including:

- Booklets: Enhance your design with subtle touches of elegance.

- Brochures: It adds a glossy finish to promotional brochures.

- Menus: Postcards can benefit from the high-gloss look to highlight images.

- Flyers: For an attention-grabbing finish, consider Clear Ink Spot Varnish on Flyers.

Instead of considering clear ink as a budget Spot UV option, the thinner application and reduced vibrancy of its gloss effect make it the perfect finish for many marketing materials. Offering a more subtle gloss effect and increased flexibility on lighter-weight paper stock.

The Takeaway

In the world of print design, the choice between Raised Spot UV and Clear Ink Spot Varnish depends on your project’s specific needs and budget. Both techniques offer distinct advantages, enhancing the visual and tactile appeal of your printed materials.

To make a well-informed decision, consider your project’s requirements, target audience, and budget constraints. Whichever option you choose, you can be sure that your printed materials will have that extra oomph to leave a lasting impression.

One thing to keep in mind though. Although very similar, it’s best not to think of them as interchangeable solutions. A design concept using Raised Spot UV would likely be very different from one using Ink Spot Varnish.

At Hue Marketing we use our design and print experience to maximize the impact of your budget. This means understanding and navigating the strengths and weaknesses of materials, finishes, folds, colours, layouts, budgets, and timing of all the marketing collateral we produce. It’s a fine-balancing act between a budget and best, so we always recommend using our Budget Calculator to help establish a project budget that protects your ROI and maximizes your chance of successfully achieving your objective.

Spot UV Frequently Asked Questions

Want to add a question? Write it in the comments section and I’ll keep them updated.

What is the difference between Raised Spot UV and Clear Ink Spot Varnish?

Raised Spot UV creates a raised texture, while Clear Ink Spot Varnish offers a glossy finish. The former is tactile, while the latter is smooth.

Is Raised Spot UV more expensive than Clear Ink Spot Varnish?

Yes, Raised Spot UV is generally more expensive due to the additional printing processes involved.

Which projects are suitable for Raised Spot UV?

Raised Spot UV is ideal for business cards, invitations, luxury packaging, and branding materials.

Where is Clear Ink Spot Varnish commonly used?

Clear Ink Spot Varnish is versatile and works well for brochures, postcards, and flyers, among other printed materials.

Are both techniques durable?

Raised Spot UV is more durable and can withstand wear and tear, while Clear Ink Spot Varnish may wear off over time.

How do I prepare my design files for Raised Spot UV and Clear Ink Spot Varnish?

To prepare your design files, create separate layers for the areas you want to apply these techniques to. Use vector graphics and provide clear instructions to your printer.

Different printers prefer the spot UV layers to be indicated in different ways, so it’s a good idea to check with your printer from the start.

Are there any limitations to the type of paper I can use with these techniques?

Both Raised Spot UV and Clear Ink Spot Varnish work well with a variety of paper types. However, printing capabilities are improving all the time, so it’s best to consult with your printer to determine the most suitable paper for your project.

Do you recommend Clear Ink Spot Varnish for business cards?

We prefer a super stiff card stock for business cards which isn’t available with the Clear Ink Varnish. So it’s not always our first choice. However, the weight of the card stock needs to be balanced against the speed of printing and budget. In that case, we’ll take a different design approach for Clear Ink Spot Varnish to maximize the effect and impact.

Does Raised Spot UV or Clear Ink Spot Varnish affect the turnaround time for printing?

Yes, both techniques may extend the turnaround time for printing, as they involve additional processes. It’s important to discuss the timeline and plan ahead to increase your options. Generally, when it comes to printing anything, the more time you have the lower the cost.

Are there any specific design considerations to keep in mind when using these techniques for branding and logos?

Yes, there’s a few. Mostly to do with minimum line weights and distances between lines. When using Raised Spot UV and Clear Ink Spot Varnish for branding and logos, ensure that your design elements are clear and well-defined. These techniques can enhance the visual impact of your brand, so choose design elements that represent your brand effectively.

Hue Marketing Founder

Seasoned marketing strategist and information junkie, with over 25 years of hands-on marketing experience. Phuket based since 2003.

Leave a Reply

Want to join the discussion?Feel free to contribute!